In the search for new, sustainable fish feed ingredients, Norwegian researchers are working to see if the ingredients can be used in feed technically. Tor Andreas Samuelsen and colleagues at Nofima have several advanced techniques in store. Samuelsen said it is underestimated how important it is that new ingredients being introduced to fish feed actually have the correct technical quality. Some ingredients require too much water, others require too high temperature, while others disrupt the structural properties of the pellet – a bit like when you end up with a failed dough in your kitchen at home. “If you cannot produce feed with high physical quality, it will crush into pieces before it reaches fish, and fish will not be able to eat it,” said Samuelsen.

As part of the EU projects AQUABIOPRO-FIT (funded by BBI JU Horizon2020) and FutureEUAqua (funded by Horizon 2020), as well as the Swedish VINNOVA-funded project Marine Feed, researchers found that tunicate meal meets the nutritional requirements for ingredients that can replace some of the fish and soybean meal commonly used in feed.

Tunicate meal consists of dried and ground tunicates, a kind of sea squirt which feeds on microalgae in the sea. Tunicate meal is rich in the essential amino acids that fish need to build protein, but there’s still work to be done to reduce its salt content. Samuelsen tested the technical quality of tunicate meal and how much can be used in the feed.

Feed analysis with a CT scanner

Feed trials were produced at the feed technology center in Bergen. First, feed mixtures with different levels of tunicate meal were fed into an extruder where the mixtures were cooked, kneaded, expanded and dried into pellets with a porous structure. The pores were then filled with rapeseed oil and then subjected to an oil leakage test.

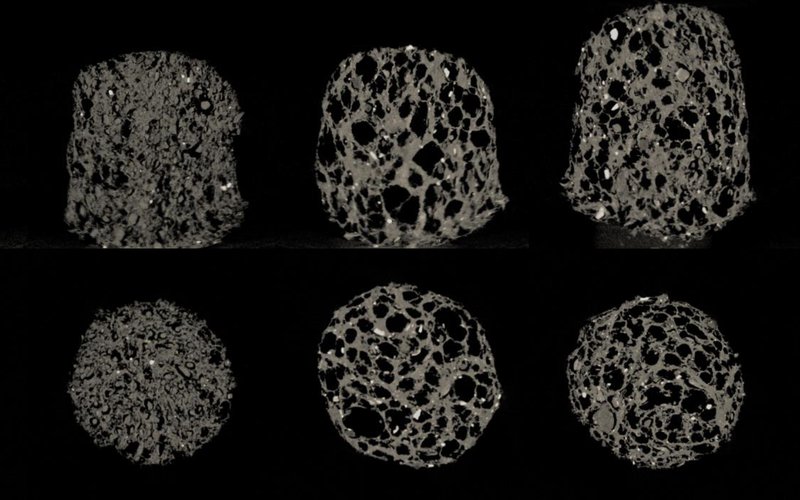

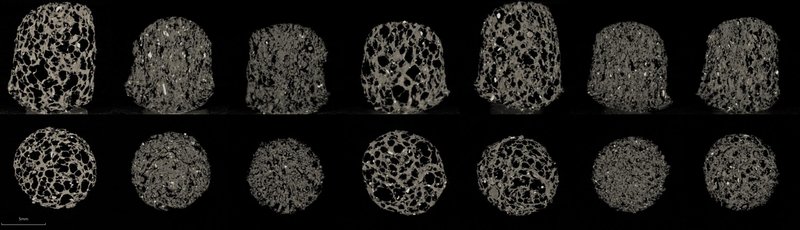

Samuelsen used a CT scanner to examine the microstructure inside the pellet. A CT scanner is an advanced X-ray device which makes it possible to see the 3D structure without slicing the pellet.

“By studying the pellet’s inner structure, we gain a detailed understanding, for example, on how various ingredients affect the pore structure,” said Samuelsen.

The scan showed that feed pellets with a large percentage of tunicate meal had large pores. The pellet with the largest pores adsorbed the highest amount of oil but also resulted in the highest oil leakage.

Determining the maximum amount of tunicate meal

By running a mixed design experiment in the statistics program, he has set some quality requirements for the pellet when adding tunicate meal to the feed. “I want as much tunicate meal as possible in the feed mixture, but the pellet still needs to be of high physical quality and as porous as possible to make it adsorb the necessary quantities of oil. It also needs to have high water stability.” Samuelsen found that 50% of the fishmeal could be replaced by tunicate meal without compromising the physical quality of the feed.

Advanced tools

New ingredients that may be interesting to use in fish feed are constantly emerging. The work on tunicate meal is a good example of how important it is to have advanced tools for studying ingredients and feed, said Samuelsen. “We need to understand why ingredients differ from each other to be able to model the production process and physical properties of the feed before we start.”

Such new tools are now available through the Aquafeed Technology Centre (ATC) which is hosted by Nofima. This is part of the Norwegian roadmap for research infrastructure which is carried out in cooperation with Norce and the University of Bergen. ATC provides the industry with access to state-of-the-art laboratories and pilot-scale facilities to be able to meet the future needs of research, process and product development. “ATC gives Nofima a unique opportunity to help the industry develop and characterize new, sustainable ingredients,” said Samuelsen.