Fischtechnik International Engineering to use geothermal energy for Swiss aquaculture system

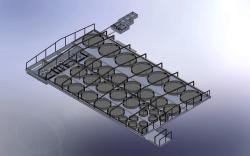

From June 2009 the Swiss will be able to look forward to European perch from a new domestic production source. Fischtechnik International Engineering GmbH is currently building a recirculating aquaculture system in Raron in the Swiss canton of Valais. In future, 300 tonnes a year of this popular fish, known in Switzerland as Egli, will be produced and processed at the site. But what makes the project particularly interesting is that warm water from the new Lötschberg Tunnel will be used for the fish farm. The water flows out of the tunnel at a constant 18° C – an ideal growth temperature for the fish.

Some 12 000 tonnes of European perch are eaten in Switzerland every year and, since traditional lake fisheries cannot deliver such quantities, large amounts are imported from eastern Europe. The European perch is reckoned to have good prospects as an aquaculture species, however. In particular, the low target weight when sold – fish of 150-200g are preferred – makes the species interesting for growers, as the fish grow relatively rapidly at this stage.

The main reason that European perch is a species new to aquaculture, and one that has not yet been farmed on such a large scale as salmon, trout or carp, is its sensitivity when reared in commercial fisheries. “The water from the Lötschberg Tunnel will provide the fish in our recirculating aquaculture system at Raron with an ideal temperature for growth,” explains FTIE managing director and aquaculture expert Dr Gerd-Uwe Meylahn. “The water will be mechanically and biologically purified and treated using the latest technology to provide the fish with an excellent environment and growth conditions. And only ultraviolet light and ozone will be used to disinfect the water in order to prevent disease.”

Indeed careful husbanding of resources has been central to the planning process. Solar panels for power generation will be installed on the roof of the fishery building. Heat will be recycled using modern thermal heat pumps. And thanks to the components of the system, many of them patented, it will be possible to keep emissions to a minimum while purifying and disinfecting the effluent from the fish farm in the unit’s own wastewater plant. The resulting sludge is in demand from farmers for use as fertiliser or can be mixed with fish processing waste and fully composted in a local composting plant.

As yet there are no Egli growing in the aquaculture system in Raron, but the production facility and the wastewater plant are nearing completion. Installation of the aquaculture system components is due to begin in January 2009. If everything goes to plan, Gerd-Uwe Meylahn expects to see the first European perch harvested from Raron in January 2010.

Fischtechnik International Engineering GmbH specialises in systems for intensive, low environmental impact fish farming. Chief focus is recirculation aquaculture systems that use a minimum of water and electricity. Since the water is disinfected using ultraviolet light and ozone, no chemicals or antibiotics are required. Close links to research institutes, universities and specialised companies all over the world ensure state of the art systems of the highest technical and biotechnical standard.