The Vibriolyte Project

A novel anti-bacterial agent addressing a critical need in a large and growing market

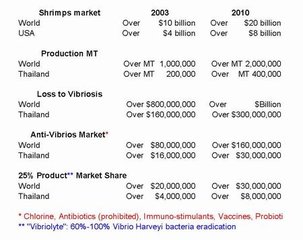

The Market

The UN FAO estimates that half of the world’s seafood demand will be met by aquaculture in 2020, as wild capture fisheries are overexploited and are in decline.

Shrimp (or prawn) culture is widespread throughout the tropical world.

It is an industry set for a period of strongly growing demand, and is currently estimated at more than 1MMT worth over US$10 billion.

US shrimps imports in 2003 exceed 475 000 tons, compared with 2002 imports of 429,303 tons, worth $3.4bn.

In 2002, over 115,000 tons were exported to the US from Thailand alone.

Penaeus monodon, the black tiger shrimp, is the most widely cultured species.

Production of farmed Black Tiger Shrimp has grown at the phenomenal rate of 20-30% per year in the last two decades.

The Problem

In much of the world, the shrimp aquaculture industry is beset by disease, in great part due to Vibrio harveyi, the origin of significant losses in the shrimp breedings.

The infection results in an anorexia, a delay of growth, and a deceleration of the stroke. The animals become opaque, possibly luminescent, and present a tissue degeneration of the hepatopancreas.

Such infections were described in Australia, Ecuador, India, Indonesia, the Philippines, Taiwan and Thailand in various shrimp species.

Periodical outbreaks have decimated entire stocks, with farmers abandoning infected ponds or despairing of shrimp cultivation altogether.

Only in recent years has the virulence of this species been recognized in an expanding list of cultured marine animals particularly in penaeids in Asia and Australia

The infection, a.k.a. Penaeid Vibriois or Luminescent Vibriosis or Penaeid bacterial septicemia or Red-Leg disease or "Sien Dun" in Thai (black splint) or Sea Gull syndrome or Sindrome Gaviota in Latin America, result in death of up to ninety percent of the crops, with the most significant impact on post-larvae and juvenile shrimp.

Recent collapses of the shrimp industry in Vietnam, India, Bangladesh, the Philippines and China have been attributed to an increase in the incidence of Vibriois.

Shrimp farms are vulnerable to total collapse, a sudden population crash that totally wipes out production. Collapses bring serious financial, social, and environmental problems for the countries concerned. After a collapse, ponds are often abandoned. Derelict areas cause serious environmental problems due to the high levels of pollutants remaining in the soil which prevents other agricultural uses.

High population densities, protein-rich feed, suboptimal rearing conditions and tropical climates – provide for an ideal environment for opportunistic Vibrio harveyi, with high mortalities being the result.

(Though not within the scope of this project, it would be important to note that a recent research has shown that out of 19 Vibrio harveyi isolates obtained from a diversity of hosts and geographical locations, 14 were also pathogenic to rainbow trout, Oncorhynchus mykiss (Walbaum), and Atlantic salmon, Salmo salar L.)

The Wrong Answer

Antibiotics, which have been used in large quantities, are oftentimes ineffective, as antibiotic-resistance forms very rapidly in contained systems such as ponds, resulting also in increased virulence of pathogens and worse, promote transfer of antibiotic-resistance to human pathogens.

In Thailand, a highly virulent strain of luminous Vibrio had developed in response to the use colloidal silver with antibiotics.

Chlorine, widely used to kill zooplankton before stocking shrimp in hatcheries and ponds, stimulates the development of multiple antibiotic-resistance genes in bacteria.

Moreover, given marine Vibrio rapid growth rates, fewer competitors and the absence of algae - a swift antibiotic-resistant and virulent Vibriosis is a common occurrence as a result of Chlorine decontamination.

Throughout Asia, shrimp farmers use antibiotics in large quantities.

The antibiotics in current use include fluoroquinolones especially norfloxacin and enrofloxacin, furazolidone, oxolinic acid, oxytetracycline, trimethoprim

and sulphadiazine.

It’s been estimated, that antibiotic usage in shrimp farm production in Thailand alone, exceed 600 tons annualy, (not including hatcheries)

Vibrio spp are presently resistant to every antibiotic used, including chloramphenicol, furazolidone, oxytetracycline and streptomycin, and are more virulent than in previous years.

The Need

Regulatory authorities worldwide are progressively prohibiting the use of antibiotics and disinfectants in food production and aggressively enforce the restrictions. Shipments seizures and confiscations are commonplace.

The public is becoming increasingly wary of traces of chemicals and antibiotics in food.

Demand for organically produced food, including sea food is growing rapidly everywhere.

There’s a growing general appreciation that the solutions lie in the field of microbial ecology, not in the field of pharmacology.

The emerging practice of Probiotics (application of selected bacterial species to displace deleterious normal bacteria), which is rapidly gaining acceptance, provides for a partial passive-defensive measure only.

The Solution

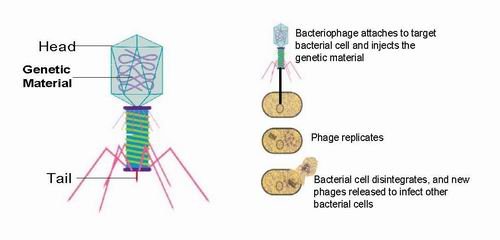

Lytic Phage Technology provides an effective, safe and ecological solution to reduce pathogenic bacteria to safe levels.

Application of Vibrio harveyi specific bacteriophages early on in the production cycle will ensure minimal presence of the pathogen in the water, sediment and animal guts, and a lingering protective effect.

Aquatic Phages

Their efficacy notwithstanding, when applied in mammals, phages face many adverse conditions. Passage of these fairly large molecules through tissues and biofilms, immune response, digestive acids, are a few examples.

Aquatic media is ideal for phages dissemination, adsorption and survival.

Emerging research of phage applications in aquaculture

• Res Microbiol. 2002 Jan-Feb; 153(1): 13-8. Bacteriophage therapy of infectious diseases in aquaculture. Nakai T, Park SC. Laboratory of Fish Pathology, Faculty of Applied Biological Science, Hiroshima University, Higashihiroshima, Japan.

• Dis Aquat Organ. 2003 Jan 22; 53(1): 33-9. Bacteriophage control of Pseudomonas plecoglossicida infection in ayu Plecoglossus altivelis. Park SC, Nakai T. Fish Pathobiology Laboratory, Graduate School of Biosphere Science, Hiroshima University, Higashihiroshima 739-8528, Japan.

• Los bacteriófagos como herramienta para combatir infecciones en acuicultura [ Ronda,C., Vázquez,M., López,R. (2003). Revista AquaTIC 18:3-10.

• Morrison, S., and Rainnie, D.J. 2004. Bacteriophage therapy: an alternative to antibiotic therapy in aquaculture? Can. Tech. Rep. Fish. Aquat. Sci. 2532: v + 23 p.

The State of the Art

Production costs as dictated by conventional fermentation production methods, present a formidable barrier towards non-clinical, low-end and high volume types of applications.

Moreover, complete purification of the phages from bacterial debris as required by existing standards for therapeutics – will further render the end product prohibitively expensive.

Delivery of phages whilst maintaining viability and concentrations in aquatic media presents a challenge.

The Company

Originally set up in 2000 for the purpose of developing phage clinical therapeutics, the team is comprised of infectious diseases specialists and bacteriophages researchers.

The company developed its core technology in phage formulations and industrial production processes.

Phage Biotech Ltd. is engaged in a strategic partnership with “Immunopreparat”, Russia.

The Development Team

• Prof. Timothy Flegel – Centex Shrimp

• Ph.D. Sergey Bujanover – Chief Scientist

• Dr. Tirasak Pasharawipas - Researcher

• Prof. Natalia N. Voroshilova, M.D. (Immunopreparat) – Phages Specialist

The Missions

• Lead in the development of bacteriophage anti-bacterials

• Develop and control bacteriophage production technologies

• Provide critical products and services for the emerging market for phage products

• Provide critical products and services for animal feed ingredients and aquatic additives.

The Collaboation

• SBBU www.shrimpbiotec.com/eng/RandD.html ,

• Centex Shrimp www.sc.mahidol.ac.th/research/shrimp.htmThailand

• Advanced BioNutrition Corp mharel@advancedbionutrition.com

The Core Technology

• Phage High Titer Production

• Phage Adsorption Enhancement

• Rapid Phage Isolation and Typing (Proprietary)

Proprietary IP

• Extant phages collections

• Proprietary formulations

• Wild phages isolation and matching expertise

Market

• Aquaculture Additives

• Shrimp Hatcheries

• Shrimp Breeders

The Product Description

Vibrio harveyi specific bacteriophage mixture

An additive for the prevention of V.harveyi related Vibriosis

COMPOSITION

A mixture of V.Harveyi lytic phagolysate filtrates

EFFECT

The preparation produces lysis of the specified strains

APPLICATION

The preparation is to be mixed with feed pellets or mixed into water.

For best effect, combine with Probionts

RECOMMENDED DOSAGE

1 Liter to 1,000 L at 10^5 PFU

SIDE EFFECT AND CONTRAINDICATION

No complications defined. No contraindications.

PACKAGING

1liter bottles

STORAGE CONDITIONS

To be stores at the temperature of + 2°C to +10°C in a dry, dark place

VALIDITY PERIOD

24 months

More information:

Centex Shrimp

Mahidol University

Bangkok 10400, Thailand

Tel: (02) 2015870

sctwf@mahidol.ac.th

Phage Biotech Ltd.

4, Pekeris St.

Rehovot 76702, Israel

Tel: (03)-9471837

info@phage-biotech.com