Wenger Manufacturing and Extru-Tech, Inc. (both of Sabetha, Kansas, US) have unveiled plans that include facility expansions for 2006 as well as enhancements and additions to their Extrusion Product Lines to address specific market needs and trends.

“As both businesses have grown, we remain steadfast in our efforts to upgrade each manufacturing infrastructure,” said

It was also announced that Extru-Tech, Inc. will expand their Sabetha, KS manufacturing facility with a planned 9,000 square foot addition. The company expects to complete construction of the building in middle to late 2006. “We continue to experience consistent growth in the sales of the complete line of Extru-Tech, Inc. Extrusion Processing Systems,” said

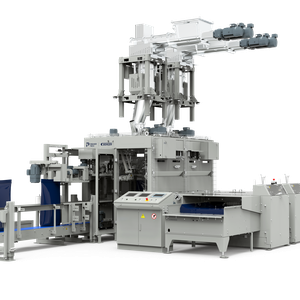

Consistent with a long track record of extrusion innovations, Wenger Manufacturing is introducing the MAGNUM ST Twin Screw Line. The MAGNUM ST Line includes enhancements to the feature rich Wenger MAGNUM Twin Screw Extruder Line.

A newly released enhancement to the Extru-Tech, Inc. Extrusion Line is the E800 Cooking Extrusion System. This is an inline system including a Bin/Feeder combination and newly engineered Conditioning Cylinder specifically designed for Aquatic Feed production. The E800 is designed for expansion to accommodate higher capacity production rates in the future without loss of the original investment.

“Major influences in aquaculture development have seen the industry evolve from a traditional practice to a science based activity and grow into a significant food production sector,” said

Through a full compliment of engineering and manufacturing operations, coupled with extensive research and development, both Wenger and Extru-Tech have created a successful formula for efficiently supplying targeted solutions to our industry. “In an era when most seek to diversify to minimize risk, Wenger and Extru-Tech remain focused on the needs – and developing potentials – of cereal grain extrusion processing”.

Wenger Manufacturing is the world’s leading supplier for extrusion processing solutions for the feed and food processing industries. “We continue to shape extrusion with a world of new ideas”.

Extru-Tech, Inc. currently produces and markets one of the feed and food processing industry’s most complete lines of superior extrusion processing systems.