Green Plains Inc. announced the successful startup of its high protein ingredient production facility and the first shipment of the product from its biorefinery in Shenandoah, Iowa, USA. The shipment is destined for one of the premier ingredient processors and suppliers in the pet food industry. The company said that it has already sold a majority of its planned high protein production for 2020.

“The completion of our first high protein ingredient production project represents a major milestone in our strategy to diversify our earnings and transition towards the creation of more sustainable high-value products,” said Todd Becker, president and chief executive officer of Green Plains Inc. “We can now provide a high-quality protein feed product to the pet and aquaculture markets, extracting additional value from each kernel of corn we process in order to meet the growing worldwide demand for protein and novel feed ingredients. Our initial shipments averaged 51% protein, compared to traditional distillers' grains, which average 30%.”

The high protein feed ingredient is produced using Fluid Quip Technologies’ patented Maximized Stillage Co-products (MSC™) system which adds a high-value product to the company’s portfolio and is expected to provide an initial uplift of approximately 15 to 20 cents per gallon to the overall margin structure. The newly constructed MSC system at Shenandoah represents a $38 million investment. Shenandoah now has the capacity to produce up to 50,000 tons of high protein feed ingredients annually and has increased the annual corn oil production capacity at Shenandoah by 20%.

“The successful startup at Shenandoah demonstrates our continued commitment to our total transformation plan to become a world-class provider of sustainable, high protein and novel feed ingredients while continuing to produce low carbon, closed-loop and sustainable biofuels,” added Becker. “We are excited to implement this technology across our platform and collaborate with our biotechnology partners to further increase margins and add value to the products we produce. We will continue to refine formulations for our aquaculture feed customers using optimal aquafeed’s world-class aqua lab located next to our high protein production facility in order to provide our customers with innovative solutions to increase feed conversions and help them transition to products that do not increase acreage expansion globally.”

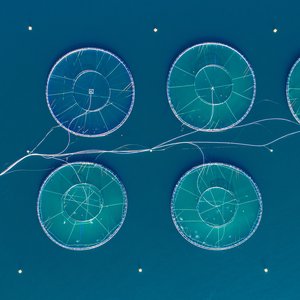

Green Plains, Shenandoah is now a complete end to end biorefining campus with the capacity to process approximately 28 million bushels of corn annually, produce 82 million gallons of low carbon, closed-loop biofuels, 50,000 tons of high protein pet and aquaculture feed ingredients, 160,000 tons of post-MSC dried distillers’ grains, and 31 million pounds of corn oil, along with an onsite aquaculture laboratory and testing facility.