NovoBind has developed novel biotherapeutic solutions based on single-domain antibodies, which they have named NBX (an acronym for NovoBind X-factor). Initially designed as a preventative measure to reduce infections, NBXs have demonstrated therapeutic potential for sick animals.

The idea

NovoBind's origins are rooted in the innovative thinking of a group of global citizens, bound together by friendship and a common drive to solve existential threats of antibiotic resistance. "Our motivation stemmed from growing concerns about antibiotic resistance, the consequences of antibiotic use in the environment, and how these threats would compromise the lives of our children and grandchildren," Sylvia Cheung, head of operations at NovoBind Livestock Therapeutics, told Aquafeed.com. "After an exhaustive review of available and novel solutions, nanobodies fascinated us."

Nanobodies, or single-domain antibodies, are derived from a particular antibody only found in camelids (e.g., llamas) and sharks. Like conventional antibodies, nanobodies provide a precise binding capability to target and neutralize the weapon systems of pathogens; however, their sustainability is unparalleled while improving animal welfare and farming practices.

The team designed a clear path to near-term revenues via a biotech business model and launched NovoBind in 2016. "Our mission was clear: we would bring the benefits of therapeutic NBXs to farmers, making them accessible through feed additives and water products," Cheung explained. Typically, human therapeutics take 20 years and approximately $1B to reach patients. The company has conducted clinical trials in patients (poultry, shrimp, etc.) in a fraction of the time and cost.

"We decided to focus on the diseases of animals raised for consumption, specifically those that cause producers billions of dollars of annual losses. For example, in aquaculture, Early Mortality Syndrome (EMS) has been responsible for a loss of approximately $2B to shrimp producers," Cheung stated.

The company raised a Series A investment in 2020 that allowed the upgrade of the laboratory facilities in 2021 and the expansion of the scientific team. It also conducted clinical trials in two leading diseases, one affecting shrimp (EMS) and one concerning poultry (necrotic enteritis).

Maple is among the group of llamas in Canada that are used to produce the specific antibodies from which nanobodies are derived. Credits: NovoBind

Production and applications

NBXs are produced using basic bioproduction methods and probiotics. The efficient and low-cost synthesis of NBXs is streamlined and primarily bio-produced using yeast. This cost-effective process involves integrating the nanobody DNA into yeast genomes to instruct yeast on the production and secretion of NBXs. The culture medium containing the secreted NBXs undergoes minimal downstream processing, resulting in a dry powder that can be easily incorporated into animal feed.

"We are most excited about delivering live probiotics that can remedy the environment and enhance the microbiome, providing dietary benefits while producing and delivering our NBXs. Beneficial probiotic bacteria are already used in shrimp farming as feed additives and water remediation. Similar bio-production is also feasible with algae, another feed additive used in shrimp farming," Cheung explained.

The NBX platform

NBXs have several advantages, including high efficiency and specificity, reduced risk of microbial resistance, easy incorporation into already existing farming processes, and cost.

Specifically, NBXs are ~12x smaller than conventional egg-based antibodies, allowing them to reach targets previously inaccessible. They are engineered to be pathogen-specific, disrupting the pathogen-host interaction and impeding the onset of infection mechanisms without killing the pathogen, thus reducing the selective pressure to develop resistance while maintaining the balance of the animal microbiome. Moreover, using probiotics for NBX production provides the additional benefits of maintaining healthy bacterial communities, favoring the shrimp's gut health, and maintaining good water quality.

NovoBind's NBXs are uniquely selected and engineered for heat, protease, pH, and salinity stability, seamlessly integrating them into existing industrial processes. They also synergize with existing and evolving disease control strategies, with the potential of smoothly becoming part of current farming practices without needing a significant redesign.

Reducing EMS-related shrimp mortality

NovoBind partnered with ShrimpVet (Vietnam) to test NBXs under controlled settings, specifically the efficiency of NBXs against early mortality syndrome disease (EMS) caused by a toxin from Vibrio parahaemolyticus in whiteleg shrimp (Litopenaeus vannamei).

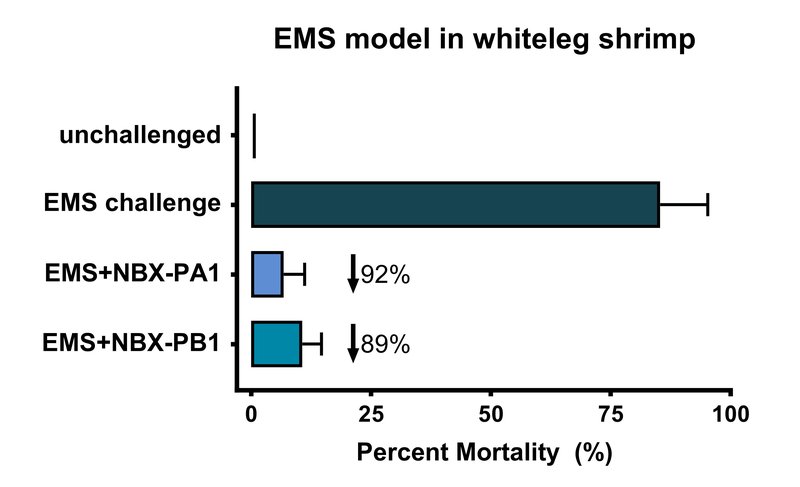

"Using whiteleg shrimp post-larvae, we have obtained promising results. In our first trial, Vibrio NBXs demonstrated a remarkable reduction in EMS-related shrimp mortality, decreasing it from a staggering 90% to less than 10%. These efficacy findings are encouraging and first in class for preventative and curative applications," Cheung explained.

Results showing NovoBind's lead nanobodies, NBX-PA1 and NBX-PB1, reducing mortality in a shrimp model of early mortality syndrome. Credits: NovoBind

The company is also testing NBXs against the white spot syndrome disease caused by the white spot syndrome virus (WSSV), with expected results within 12 months.

An affordable solution

There are two key strategies to consider regarding production. One is toll manufacturing of NBX or probiotics producing NBXs, and the second is NBXs' co-production with existing products.

In terms of toll manufacturing and based on the company's estimations, the production of NBXs is expected to be more cost-effective than conventional antibodies, RNAi, and phage, and less challenging than antimicrobial peptides, positioning them for a range that farmers and producers will welcome.

"Co-production strategies offer unprecedented advantages, allowing NBXs to be bio-produced by many partners with exciting biological solutions at minimal additional cost. Co-production will be possible by leveraging the partners existing biological extract, probiotics, and prebiotic manufacturing processes, ensuring that NBXs are inclusive to all farming procedures, from commercial infrastructure to family-owned operations. This method not only adds targeted functionality to existing high-quality products but also reduces the risk to existing operations as the end users do not have to deal with the insecurity of changing one biological control for another; it is simply additive and synergistic," Cheung stated.

NovoBind's business model revolves around developing and securing intellectual property assets for innovative biotherapeutic solutions to combat major animal diseases. "We aim to commercialize these assets by partnering with established global animal health, bio-control, feed and feed additive players. Our proprietary technology empowers these companies to create disruptive and unique feed products that can command premium efficacy while maintaining an attractive cost of production," Cheung explained. "Thus, with our tools, feed producers can address devastating animal diseases, minimizing reliance on antibiotics and offering consumers antibiotic-free or responsibly raised food products. This approach becomes increasingly vital as global regulatory restrictions on antibiotics and anti-infectives grow and as resistance diminishes their effectiveness," Cheung added.

Looking forward

The company's immediate focus is developing and optimizing its NBX solutions for EMS in whiteleg shrimp. "Given the highly encouraging data for EMS, we are pursuing commercial validation in hatcheries and subsequently in grow-out ponds," Cheung said.

NovoBind's growth projections are promising and extend beyond the aquaculture sector. "We have a diverse portfolio of products designed to address diseases in poultry (e.g., necrotic enteritis, salmonellosis, and coccidiosis) and pets (e.g., parvovirus). This broad portfolio represents an additional market opportunity for NovoBind, estimated at approximately $25B in annual losses to producers," Cheung explained.

"Our necrotic enteritis NBXs have also demonstrated impressive results in poultry trials, significantly reducing mortality by 68% (from 24% to 7.5%) while recovering 77% of the loss in feed conversion caused by the disease. We are exploring various partnerships for validation in large barn trials and commercial broilers."

These compelling outcomes against diseases affecting different host animals open the door to expanding NBX applications, reaching beyond aquaculture and animals raised for consumption to address conditions in companion animals, crop protection, and alternative protein production.

NovoBind is now seeking funding to progress into the next stages of development, which include scaled production, product optimization, and large-scale animal studies. "We are actively seeking commercial partners and investors to join us in bringing our first products to farmers," Cheung said. "We are experiencing solid interest in the recently launched commercialization round, and several specialty VCs and global strategics are showing great interest in partnering for specific products and in specific geographies, signifying the recognition of our innovative approach."

"We find motivation in the belief that our work can help farmers meet growing food demands while sustaining their income security. We are humbled and thrilled to work with first-class change makers stemming the full spectrum of the innovation ecosystem from investors, strategic partners, collaborators, and the public sector to bring this transformative nanobody (NBX) solution to every farmer worldwide. Working as one, we have the power to shape a better future," Cheung concluded.