Tunicate (Ciona intestinalis) meal has been recently studied as an alternative ingredient to substitute fishmeal protein in Atlantic salmon diets. Previous studies found that at a dietary level of approximately 17%, substituting 50% of dietary fishmeal protein shows promising results in terms of growth, biometrics, fillet and liver total lipids and fatty acid profile and tissue morphology.

As a new potential ingredient, there is still lack of knowledge on how it would affect the extrusion process. Researchers from the Aquafeed Technology Center evaluated the effect of the replacement of fishmeal or soy protein concentrate by tunicate meal on the extrusion process, physical pellet quality, pellet expansion and microstructure.

The experiment was based on a three-component simplex-centroid mixture design. Models with R2 in the range of 0.574–0.999 (P = 0.03 to < 0.0001) were established for specific mechanical energy (SME), temperature behind extruder die (Tdie), apparent dough viscosity in the extruder die (Vdie), pellet hardness, durability, expansion, and microstructure parameters.

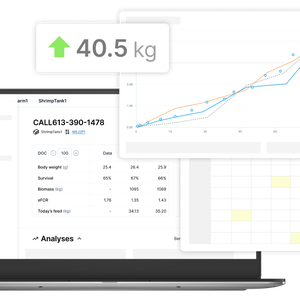

Increase in SME and Tdie were mainly explained by the reduced lipid content in the feed mix due to the replacement of FM with tunicate or SPC. Reduced Vdie was mainly an effect of increased tunicate level and with the lowest value found for the pure tunicate blend. There was an increase in volumetric expansion and open porosity by the replacement of SPC with tunicate, explained by this decrease in Vdie. Reduced hardness and durability were found for blends high in SPC due to incomplete plasticisation. Extrudate expansion, fat adsorption capacity and leakage were explained by the extrudate microstructure measured by X-ray microtomography.

Within the boundary of the chosen design, 64% of the fishmeal can be replaced by tunicate meal without compromising physical feed quality, researchers found. Due to its viscosity behavior, tunicate meal can improve pellet expansion and fat absorption capacity of extruded feed, they concluded.

Check out the study here.