FORWARD:

It’s time to re-think Least-Cost Formulation in Shrimp Starter Feeds

Dr. Jeremy Javers, Ph.D. and Vice President of Technology for Houdek

Fermentation has changed how animal feed is formulated. And we’ve seen it coming for quite a while!

Though the details have not always been apparent, the fermentation of foods and animal feed has played a significant role in human civilization. Preservation of foods by fermentation is an ancient technique utilized still today in products like pickled foods, sauerkraut, yoghurt, sausage, cheese, and kimchi. However, fermentation is also utilized for the production of alcohols, antibiotics, enzymes, specialized fats and oils, nutraceuticals, prebiotics, and postbiotics.

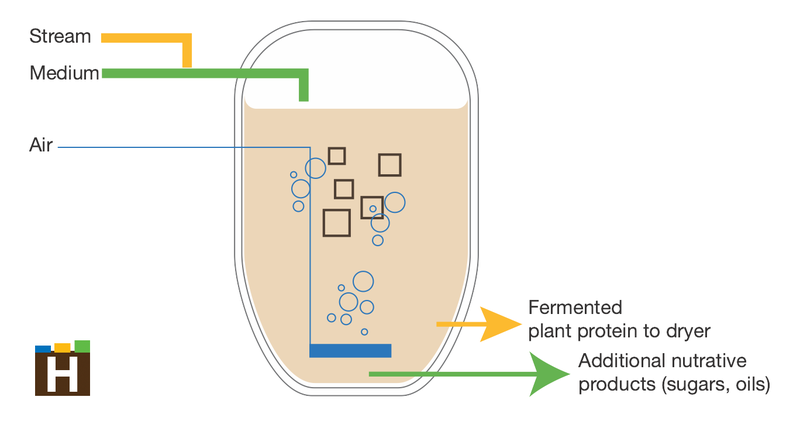

The end result of fermentation is determined by one of three primary sources of the fermentation process — bacterial, yeast and fungal. In addition to the sources, fermentation occurs in one of two environments — anaerobic (without air) and aerobic (with air). Though anaerobic and aerobic fermentation are both utilized to create new, positive products, aerobic fermentation is increasingly proving its worth with extraordinary results.

With the 20th century’s rapid advancements in understanding genetics, DNA, biology, and biotics, a better understanding of aerobic fermentation unlocked new opportunities to develop and produce beneficial products. Many of the past decades’ advancements in nutrition have been obtained through aerobic fermentation.

In aerobic fermentation, specialized tanks up to hundreds of thousands of liters in size are utilized. These tanks (bioreactors) have much stricter design and operational characteristics when compared to the tanks that operate anaerobically. Thus, aerobic bioreactors typically cost 30-50 times more than their without air counterparts. Additionally, aerobic bioreactors are operated within completely sterilized environments while anaerobic bioreactors need only be sanitized. For a different view on the difference between the two terms, think of a surgical instrument as requiring sterilization while a household dishwasher simply needs to sanitize everyday cutlery. Nevertheless, aerobic bioreactors control their processes through highly proprietary methods of mixing, feeding, oxygen, temperature and pH control.

Houdek’s utilization of fermentation is an essential part of improving aquafeeds — from improving sustainability, nutritional quality, nutritional efficiency, and adding far greater economic value!

It’s time to re-think Least-Cost Formulation in Shrimp Starter Feeds

Sergio Nates, Ph.D., Houdek

Shrimp aquaculture has experienced tremendous growth in recent years, establishing itself as a vital industry providing a significant source of protein worldwide. Essential to this success is the critical management of the feeding regime which is a complex and vital aspect of the health, growth, and sustainability of shrimp raised in controlled environments. Proper feeding practices involve a balance between nutrition, environmental impact, and economic efficiency.

It is well known that feed represents a significant portion of the production cost in shrimp aquaculture, making efficient formulations vital for economic success. The goal is to optimize nutrient composition while minimizing expenses associated with feed ingredients. As a result, feed companies have adopted the concept of least-cost formulation, which involves creating feed formulas that meet nutritional requirements at the lowest possible cost without compromising shrimp health or growth. It involves selecting ingredients based on their nutritional value, availability, and cost-effectiveness. While current methods for feed formulation are primarily based on minimizing costs, least-cost feed formulation involves a meticulous balance of various factors. Firstly, it requires an in-depth understanding of the nutritional requirements of the animals. Different species, breeds, ages, and purposes (such as growth, reproduction, or maintenance) demand specific nutrients in their diets. Therefore, it is crucial to formulate a diet that precisely meets these nutritional needs.

Additionally, the cost and availability of ingredients play a pivotal role. A wide array of feed ingredients exists, each with its own nutritional profile and price point. The challenge lies in selecting the right combination of ingredients that provide necessary nutrients at the lowest possible cost without compromising animal health and performance. Formulation software and tools have become indispensable in this process, enabling nutritionists and producers to create optimized feed formulations. These tools consider ingredient prices, nutrient content, digestibility, and other factors to generate cost-effective diets that meet nutritional requirements. However, a challenge with this approach is that certain additives or specialized ingredients, which could enhance animal health and performance, may not be adequately accounted for in least-cost formulations. Their inclusion might conflict with the cost-minimization goal, leading to compromises in diet quality. Indeed, the challenge lies in formulating feeds that meet the nutritional needs of shrimp, maintaining economic viability for farmers, and minimizing environmental impact.

After the nutritional potential of feed ingredients has been precisely determined, the addition of environmental objectives to the traditional feed formulation algorithms are beginning to play a major role. Reducing feed emissions has become critical to advancing sustainability in shrimp aquaculture.

Efforts to reduce the carbon footprint of feed ingredients often involve implementing sustainable agricultural practices, optimizing production processes, reducing waste, and exploring alternative sources of protein and nutrients. Life cycle assessments (LCAs) are commonly used to analyze and compare the environmental impact of different feed ingredients. These assessments consider factors like greenhouse gas emissions, land use, energy consumption, and water usage throughout the entire production process, from cultivation to transportation and processing.

Traceability is also crucial, especially to consumers and feed manufacturers that value knowing the full story, from production to distribution to final use, of ingredients.

Additionally, certification programs and initiatives that advocate for sustainable sourcing, such as certifications for responsibly produced soy or other feed ingredients, aim to reduce the environmental impact of feed production by promoting eco-friendly practices. Ultimately, reducing the carbon footprint of feed ingredients involves a combination of sustainable sourcing, efficient production methods, and ongoing research into alternative, environmentally friendly feed sources.

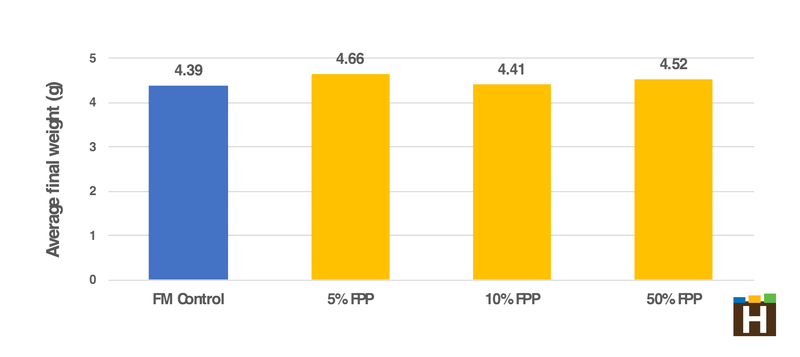

Shrimp aquaculture involves various stages and types of feeds where significant attention has been concentrated on starter feeds as shrimp require a high-quality and nutritionally balanced diet for adequate growth within the shortest time. These feeds are meticulously crafted to contain precise ratios of various nutrients and they often incorporate micronutrients and essential fatty acids that play critical roles in immune system function, disease resistance, and overall health. Beyond nutritional considerations, starter feeds also contribute to environmental sustainability in aquaculture. Efficiently utilized feeds result in better feed conversion ratios, ensuring that a higher percentage of the feed nutrients are converted into biomass rather than being lost as waste (Fig. 1).

Figure 1. Average final weight of L. vannamei (PL10) after three weeks of being fed starter feeds with different inclusion levels of a fermented plant protein

All of the factors above, combined, illustrate the particular reality facing today’s nutritionist - a reality that wasn’t part of the feedscape, thirty, twenty, or even ten years ago.

Innovation and ongoing research in feed formulation technology play a pivotal role in enhancing the efficacy of starter feeds and one innovative approach gaining traction in the industry involves incorporating fermented plant proteins into these feeds.

Today, fermented plant proteins (FPPs) offer a sustainable alternative to traditional feed ingredients like fishmeal, addressing concerns of overfishing and environmental impact. Through fermentation (Fig. 4), plant proteins undergo enzymatic breakdown by beneficial microorganisms, enhancing their digestibility and nutrient availability for shrimp.

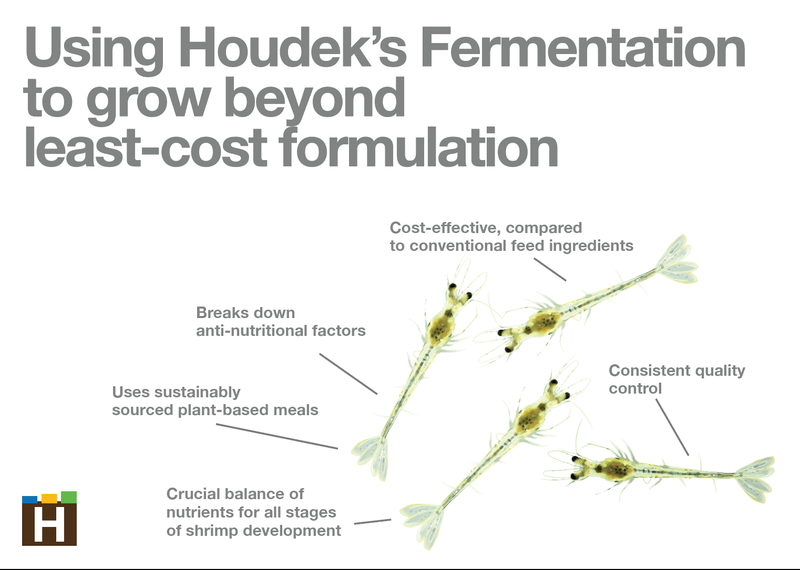

FPPs provide the Shrimp Nutritionist with several advantages (Fig. 2):

- Nutritional Value: Fermentation breaks down anti-nutritional factors, making nutrients more bioavailable for shrimp. It improves the protein quality and digestibility of plant-based ingredients, ensuring they meet the specific amino acid requirements crucial for shrimp growth.

- Sustainability: Utilizing plant-based proteins reduces reliance on marine resources, contributing to the sustainability of aquafeed production. It mitigates the pressure on fish stocks and helps alleviate concerns about the environmental impact associated with sourcing fish-based ingredients.

- Cost-Effectiveness: Incorporating fermented plant proteins can offer a cost-effective solution compared to conventional feed ingredients. While the initial processing of these ingredients may require investment, the long-term benefits in terms of availability and cost stability make them an attractive option.

- Nutrient Balance: Achieving the right balance of essential nutrients, especially amino acids, in these feeds is crucial for shrimp development. Formulating feeds with fermented plant proteins requires meticulous attention to ensure they meet the specific nutritional requirements of shrimp at different developmental stages.

- Quality Control: Consistency in the quality of fermented plant proteins is guaranteed for the reliability and effectiveness of the feeds. Maintaining standards in fermentation processes and ingredient sourcing is assured to produce high-quality starter feeds.

Figure 2. Fermentation adds greater dimension to shrimp starter feeds, compounding value that can’t be obtained adhering to the traditional least-cost formulation.

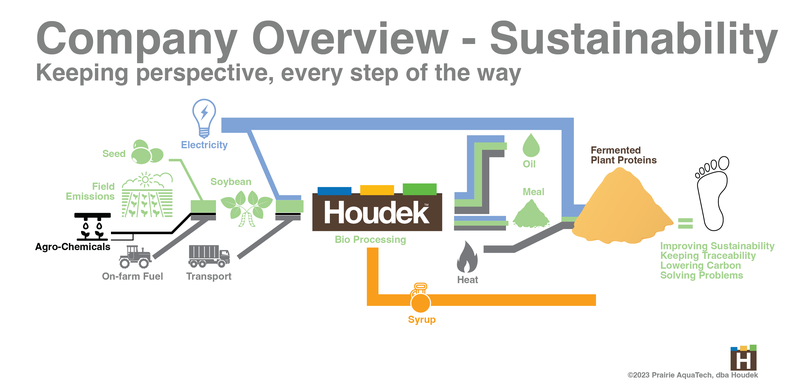

Ongoing research and development aim to address these challenges, optimizing the incorporation of fermented plant proteins into shrimp starter feeds. Innovations in fermentation techniques, formulation strategies, and ingredient combinations continue to enhance the nutritional value and palatability of these feeds while supporting sustainability objectives. In other words, feed ingredients are occupying a ‘space’ in shrimp starter feeds (and aquafeed in general) that has greater depth and dynamic (Fig. 3).

Figure 3. Sankey Diagram of Houdek’s plant protein fermentation process, resulting in ME-PRO® for aquafeed

In summary, integrating fermented plant proteins into shrimp starter feeds represents the promising avenue in the quest for sustainable, nutritionally balanced, and economically viable aquafeed solutions.

Continued advancements and collaborations within the industry will further refine this approach, fostering a more sustainable future for the shrimp aquaculture industry.

Figure 4. Simplified illustration of Houdek’s aerobic fermentation bioreactor

For more information, contact:

Sergio Nates, Ph.D.

Executive VP

Jeremy Javers, Ph.D.

VP of Technology

Jeremy.Javers@HoudekNature.com

Download:

It’s time to re-think least-cost formulation in shrimp starter feeds

Whatch video here.