BinSentry is protecting two new patents as its software gains ground in the feed supply chain industry. Focused on helping customers reduce feed waste in their facilities, optimize truck loads, and eliminate accidents from climbing bins, BinSentry has developed IoT sensors for feed inventory monitoring in feed mills and animal farmers with software tools to create alerts and suggestions streamlining operations and consequently increasing profits.

“Our customers are good at managing animal feed. We can help them be great. Every time we help them reduce feed expenses by 1%, that cost savings drops straight down to their bottom line. These companies manage inputs aggressively, and supporting their efforts to manage their largest input, animal feed, is what we do every day,” said Ben Allen, CEO at BinSentry.

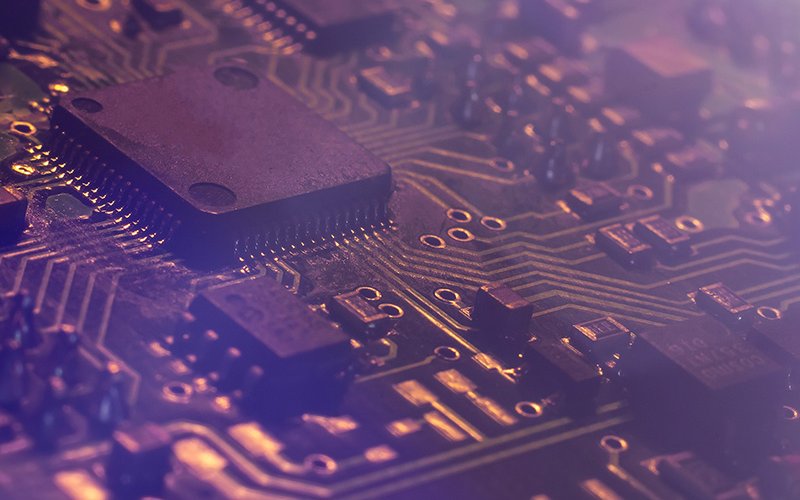

BinSentry’s new 3D optical sensors still use patented installation technology, which will increase efficiencies and worker safety for feed mills and ingredient producers providing useful data for feed inventory and management. Rapid to install, with no wires or hubs, they are powered by solar energy and can work without sunlight for an extended time. Each device is also equipped with an LTE-M modem that keeps it connected even in the most remote locations. Regarding the software, it can collect and interpret data through Artificial Intelligence (AI), and improve the information that the sensors provide unlocking cost savings for feed mills.

“Sensors are a vital part of the equation, but they need to be extremely accurate to really help. Our latest 3D sensors have proven to be more than 98% accurate, each one taking over 9,000 measurements multiple times a day to account for uneven product flow, even in humid weather,” said Nathan Hoel, CTO at BinSentry.

“BinSentry allows producers and feed mills to gain visibility to the controllable costs in their feed supply chain. Supply chain costs are typically managed by comparing them to prior performance. BinSentry’s digitization of the feed supply chain will allow producers to compare their performance to their potential, not just their past. Accurate real-time visibility of on-hand inventory, a feed consumption budget based on barn population and genetics, all seamlessly integrated with existing software tools, will provide the visibility that is critical for the industry to move from the current inefficient analog process to the digitized Mill of the Future,” said Dennis Organ, chairman of the board at BinSentry.

“The ability to create extremely accurate views into feed inventories in real-time depends on the software that BinSentry has moved to protect through patents. With two new patents filed within the last few months, BinSentry is moving to protect its lead,” said Nathan Hoel, CTO at BinSentry. “While the hardware is important, the software that allows it to be so accurate and reliable is unique to BinSentry, and we will continue to invest in this IP.”