Evonik has invested €25 million in developing and expanding its methylmercapto-propionaldehyde (MMP) production plant in Wesseling, Germany, in the latest move to strengthen its world-scale global methionine production network.

MMP is integral in the production of MetAMINO® (DL-methionine) which is used in animal feed to improve the performance of livestock farming. The precursors of this essential amino acid have been produced in Wesseling for more than 50 years.

Gaetano Blanda, head of Animal Nutrition business line, said that “with this investment, Evonik is strengthening the European methionine network to safeguard the long-term supply of MMP to our MetAMINO® production hub in Antwerp, Belgium. The move underscores our commitment to serving and expanding the global DL-methionine market and secures the best possible supply security for our customers.”

The conversion and expansion of the plant in Wesseling have been made possible by the development of a new production process, that will avoid the storage of chemical intermediates, such as acrolein, at the site.

“Evonik is known for its innovative approach and world-class technology, and in Wesseling, we have now developed a process that increases efficiency and, with responsible care in mind, further enhances safety at the site,” said Jan-Olaf Barth, head of the Essential Nutrition product line. “This investment is a building block of our global methionine asset strategy with the clear goal of being the cost and technology leader in all regions and the reliable partner for our customers.”

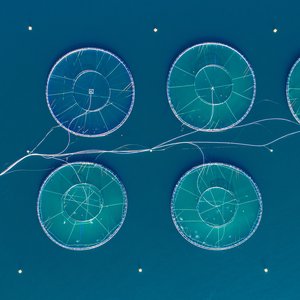

At the heart of Evonik’s methionine asset strategy are three world-class global production hubs covering Europe (Antwerp, Belgium), Asia (Singapore) and the Americas (Mobile, Alabama). Consolidating production at these hubs ensures a reliable product supply as well as offering opportunities for cost-efficient debottlenecking and future expansion.