New mixing technique significantly reduces rework

Dinnissen Process Technology and K-Tron are introducing a new variant of Pandora End of Line Mixing especially suited for significantly reducing rework. This enables companies to realize significant savings on the costs involved in the collection and removal of rework and the cleaning costs during the production process. The new mixing concept retains the original classic characteristics which have made Pandora End of Line Mixing into such a success.

Rapid, careful and extremely homogenous mixing

Pandora End of Line Mixing works according to the principle of continuous mixing, whereby raw materials are continuously added to and removed from an extremely compact mixer. This mixing concept was especially developed for situations in which high demands are placed on the rapid, careful and extremely homogeneous mixing of a maximum of 10 (micro) components.

Pandora End of Line Mixing is perfect for situations where a quick and easy switchover to new recipes and the prevention of contamination and segregation are critical factors. To accomplish this, Pandora End of Line Mixing uses several highly accurate gravimetric feeders from the K-Tron Process Group in combination with the famous Pegasus Paddle Mixer from Dinnissen Process Technology. The special feeders accurately measure the supply of ingredients to the Pegasus Paddle Mixer. The mixer, in turn, mixes the ingredients very quickly to obtain an extremely homogeneous result (coefficient of variation: 3-5% for fine powders).

The compact size of the mixing concept provides a range of significant benefits. The mixer can be cleaned quickly and easily, making a rapid switchover to a new production recipe look like child's play.

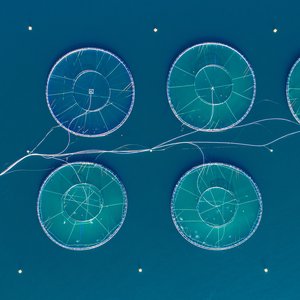

The Pandora End of Line mixing concept is suitable for processing quantities between 50 kg and 100 tons per hour. Its small size makes it possible to easily integrate the Pegasus Paddle Mixer at any location within a new or existing production process, for example just before the packaging process to minimize the risk of segregation.

Pandora End of Line Mixing is especially suitable for spraying oil and liquids onto powders, pellets and granulates.

New mixer reduces the costs of collection, recycling and cleaning

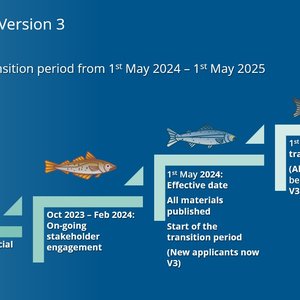

The new variant of Pandora End of Line Mixing, which Dinnissen and K-tron will be introducing to the market this summer, was specially developed to significantly reduce rework. The very accurate feeders from K-tron respond extremely quickly to the process controls. In addition, this new variant of the Pandora End of Line Mixing concept is fitted with a special batch-start-up-setting, based on intelligent cut-off valves which close off the mixer during the initial start-up phase. As a result, a (new) mixing process is carried out during the start-up phase in accordance with the principle of batch mixing, thereby reducing start-up losses.

Finally, Pandora End of Line Mixing is equipped with extremely precise control technology, which manages the entire mixing process and significantly reduces rework. This reduction of rework offers users the benefit of being able to realize significant savings with regard to investments in the collection and recycling of rework and the cleaning costs during the production process.