Insta-Pro International is world-renowned for their leading role in oilseeds processing and oil refining technology. However, keen interest from existing and new customers moved the company to also explore the aquafeed and petfood industries.

The existing extruder range from Insta-Pro is of High Shear Design, and is essential for successful processing of Oilseeds. The

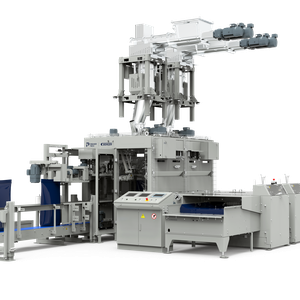

In practical terms, these latest Aquatic Feeds Extrusion developments could be summarized as follows:

New Mass-Flow Feeding Equipment

Proper and consistent feeding of the Preconditioner is essential in order to ensure smooth operation of the Extruder. The New Insta-Pro Volumetric Feeder is equipped with a Variable Pitch Screw Feeder. This, in conjunction with a Mass-Flow Bin of specific design, ensures no segregation of ingredients and therefore a very consistent end product.

The New Insta-Pro® Preconditioner is designed for optimum conditioning of Aquatic Feeds and other starchy formulations

New Preconditioners for Aquatic Feeds

The New Insta-Pro Preconditioner for Aquatic Feeds allows for controlled introduction and distribution of Water, Steam, and any other liquids or Slurries the Feed Manufacturer wishes to include in the formulation.

Liquid and Steam quality and flow are controlled by means of external Control Manifolds and Control Systems. The entire Preconditioner is constructed in heavy gauge Stainless Steel, with easy access to the bearings for maintenance purposes.

The Preconditioner Shaft and Paddles are easily accessible via a door located on the top of the Preconditioner, and allows for very easy and quick adjustment of the Paddles, if required. The New Preconditioner ensures high degrees of Starch Gelatinization, and therefore makes the Medium Shear Extrusion process that follows a predominantly shaping instead of cooking operation.

New Medium Shear Extruder Barrels

The Shear Rate of the Insta-Pro® Extruder Barrel has been lowered to levels more appropriate for Aquatic Feed manufacturing. The change in Barrel Components and characteristics allows for extrusion cooking of a complete range of Aquatic Feed formulations. Proper Preconditioning coupled with the new Extruder Barrel allows for flow conditions towards the end of the Barrel that enhances the final Shaping Operation.

The New Insta-Pro® Cutter Head for Aquatic Feeds and other Shaped Feeds and Foods

New Shaping Devices

The New Insta-Pro® Shaped Feeds and Foods Cutter Head is the final addition to the company’s newly developed Aquatic Feed manufacturing capabilities.

Special attention has been given to characteristics that will allow Feed Manufactures to produce Aquatic Feeds of very small diameter, as a result of a large available Die Open Area. The Cutter Assembly runs on high temperature bearings and is designed so that the Cutter Shaft is always perpendicular to the Cutting Surface of the Die Plate.

This feature allows the operator to set the Cutter Knives extremely close to the Cutting Surface, and thereby minimize fines production during the cutting operation. The Cutter Knives could be replaced and sharpened individually.

Final product shapes could be varied and Insta-Pro can provide Die Designs to suit specific customer requirements. Insta-Pro also offers nutritional and technical support services.

Advantages of Insta-Pro Aquatic Feeds Extrusion Technology

Insta-Pro kept the following important design goals in mind during development of their Aquatic Feed Extrusion equipment:

- To provide customers with equipment capable of producing the highest quality Aquatic Feeds

- To provide equipment at an affordable investment cost to customers.

- To provide equipment that could be used to upgrade extruders of existing customers.

- To provide equipment that will minimize the effect of aquatic feeds on the environment.

For more information, contact: Insta-Pro International: marketing@insta-pro.com; www.insta-pro.com