Feed Design Lab, a Dutch practical research and education center for innovation and sustainability in the animal feed industry, completed the renovation of its pilot plant, now fully operational.

The pilot plant

Feed Design Lab was founded in 2014 by companies in the animal feed sector and has now more than 100 partner companies from the entire sector and all over the world. The center offers a pilot plant to the animal feed industry to perform its own trials or participate in practical training. Partners are also invited to participate in innovative projects, workshops and networking events.

Starting as a 2-tons-per-hour pilot plant and following customers’ requests for smaller trials and treatments, especially for heat stability and testing the specific environment of each customer, Feed Design Lab decided to adapt the pilot plant to smaller trials (200-800 kg per hour) to increase effectiveness, perform more tests per day and optimize the production process.

The center renewed and adapted its pelleting line, the second of the three production lines that the center features: (1) Grinding and mixing, (2) Condition, pelleting extrusion, cooling and dryer, (3) Sieving and coating.

Partner companies

Eighteen partner companies contributed to the renovation, which was completed in the summer months and is now fully operational.

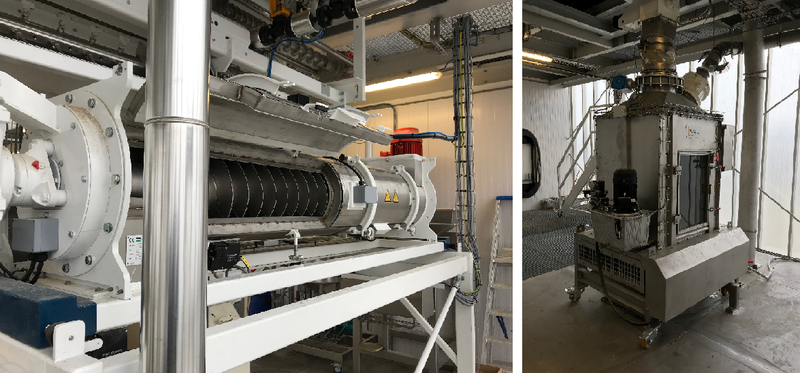

Ottevanger and PTN delivered small equipment such as a conditioner, a screw conveyor and a retention time barrel, especially important to hygienize compound feeds, aquafeeds and pet food. Other technology suppliers such as Kiekens, Arco, IVS, CPM and DMT International adapted their equipment to perform small trials. For instance, Geelen Counterflow provided a mobile cooler that can be easily used at different feed production stages.

The center also features, for the first time in a European feed mill, Steam QM-1 by Armstrong, an automatic steam quality measurement equipment.

Time retention barrel (left) and mobile cooler (right) at Feed Design Lab's pilot plant.

Available trials and services

When Feed Design lab opened in 2014, the pilot plant focused on research on new raw materials, production techniques and training activities. Now, six years later, the renewed pilot plant aims to further professionalize what Feed Design Lab is unique, in experimenting for the animal feed industry and providing practical training with activities such as:

- Recipe and process technology testing for compound feed, petfood and aquafeed.

- Heat stability: more treatments in one day.

- Pelleting: all kinds of raw materials.

- Precompacting and extrusion tests.

- Adding dry and wet waste streams in the common feed.

- Creating different retention times without adapting paddles.

- Coating on warm product and cool afterward.

- Reposting more results due to more sensors and data analysis.

- Full reporting of all process parameters and data analysis available to the customer.

International feed companies are invited to workshops and networking events and can use the pilot plant for their own tests or take part in innovative projects and courses. The center also offers tailor-made courses for companies. All partner companies receive a 25% discount on the use of the facilities and participation in courses.

“Feed Design Lab can thus make an important contribution to, among other things, the application of circular raw materials, improving animal health and reducing the CO2 footprint of animal feed,” the center said.

For more information, visit feeddesignlab.nl.