Andritz launched two innovations for the aquafeed industry at VICTAM International 2022: the Micro Feed System and Metris Vibe.

Aquafeed.com spoke with Stefan de Roo, global MarCom manager for Feed & Biofuel at Andritz, to get more insights into the innovations and how they can support aquafeed producers.

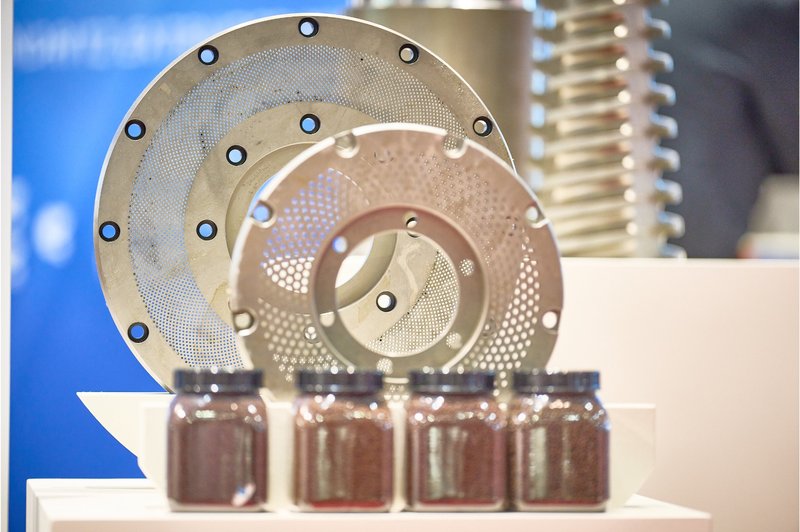

Micro Feed System

The Micro Feed System is a dedicated extruder upgrade system designed for aquafeeds that are less than 2 mm in size. The system can increase capacity by up to 40% when compared to running micro feed at reduced speeds on standard extrusion lines, and represents a breakthrough in the industry, the company said.

The Microfeed System incorporates an optimized die that can withstand the higher pressure caused by the smaller holes due to a stronger construction, larger diameter and bigger open surface, and a smart die base to create an equal distribution of the feed towards the larger die. This combination enables customers to produce micro feed at a higher capacity than with the dies used for micro feed up till today. “Right now the smallest size we have in operation is 0.6 mm sinking feed,” said de Roo.

The system does not require special preconditioning, “but preconditioning is a good thing to reach the right product quality and it is also useful for the well-being of the extruder. The need for preconditioning always depends on the raw materials, recipe, and also quality of raw materials. When producing shrimp feed, for example, there is a need for longer retention time, because we need to fully activate the low amount of starch contained in the formulation,” de Roo explained.

The production capacity of extruders normally decreases when producing micro feeds, but the company found from test results that “the Micro Feed System increases the output of the extruder by 20-45% depending on the pellet sizes and the raw materials. For example, we were able to increase capacity from 6 to 8.5 t/h producing 0.8 mm shrimp feed for one of our customers.”

When it comes to ensuring the required density ranges of feeds, de Roo said that the system uses Andritz’s Expansion Control System (ECS) to adjust the density of the sinking feed. “You can make the product lighter or heavier depending on the final product quality requirement. The Microfeed System is compatible with all Andritz single-screw extruders and the ECS, making it a superior solution for shrimp feed producers,” he explained.

In terms of energy consumption, de Roo said that “as we increase the capacity of the extruder, we will use slightly more energy from the main motor, but the kW/t product produced remains the same. At the same time, we utilize the extruder better as we produce more with the same equipment and operators, and this way, we reduce operational costs per ton of product produced.”

The Animal Feed and Nutrition Award in the category of Aquafeed was given to Andritz for its Micro Feed System at VICTAM International 2022.

Andritz Micro Feed System.

Metris Vibe

Metris Vibe is a wireless vibration and temperature sensor that can monitor the health status of mechanical equipment regardless of the manufacturer. The sensor is wireless, battery-powered and measures vibration in three directions. It has an internal memory for storing data, which is communicated through Bluetooth connectivity. It can be applied to existing equipment at feed mills.

On how feed mills can benefit from this new solution, de Roo said that “first of all, line productivity can be significantly improved by reducing the number of unplanned production stops resulting from a sudden equipment breakdown. Knowing up front when parts need replacement is the key enabler. Predictive maintenance allows feed producers to plan any repairs needed in due time and a scheduled maintenance window. Additionally, sudden breakdowns are often more costly to repair as surrounding equipment parts are often damaged as well. There is also a worker safety aspect, as tending to a sudden breakdown is one of the more dangerous tasks for maintenance teams. Our solution is unique in the way it provides specific recommendations for equipment inspection and maintenance. This is based on measured failure modes and is a 1st level service support to our customers.”

Feed mills are moving to digital factories and Andritz has a wide range of digital solutions across its business segments. “We are continually developing this area as one of our strategic targets. Specifically, on the Metris Vibe and in the area of maintenance management, we are developing more comprehensive digital solutions considering more aspects of feed production, such as equipment criticality, availability of spare parts, routine inspections and more. These elements form a total risk score per asset, and we support customers to take the needed measures to avoid any production losses and ensure the installed base capacity is utilized to the fullest,” de Roo stated.

“ANDRITZ innovates on all of its activities, from the design of equipment, engineering of solutions up to its wide range of services,” stated de Roo. “We are a global partner for complete plant solutions for feed, pet food and biomass industries, based on customers’ exact specifications at the lowest possible total cost of ownership.”

Andritz Metris Vibe.