On the occasion of the re-introduction of Processed Animal Proteins (PAP) in Aquafeeds, Sonac, a major European rendering company, organized a seminar at their production location in Burgum, the Netherlands. Around 40 invitees, representing the major aquafeed producers in Europe, attended the seminar.

First, Mr. Gert Mulderij, sales and marketing director Vion Ingredients, welcomed the attendees. He also explained the recent developments, whereby Vion Ingredients will be separated from Vion Food.

To give some background around the decision for the re-introduction, Mr Rik Herbes (NVWA, Dutch Veterinary Authorities), was invited. Mr. Rik Herbes has 25 years of experience in feed safety.

He first gave some information about the role and responsibilities of NVWA and then explained the history of the legislation to deal with BSE. The extended feed ban started in December 2000 and is now lifted for Aquaculture. The problems associated with this lift are mainly political will and consumer trust, while sustainability of PAP compared to fish meal and GMO Soybean products should be a strong argument for their utilization.

He also stressed the importance of a dedicated production line and process, to avoid any future contamination, which would seriously affect the credibility of the industry.

Mr. Eric De Muylder (CreveTec), aquafeed specialist first gave a general overview about the aquaculture and aquafeed market globally. He then gave some information about the potential and advantages of the utilization of PAP in different fish and crustacean diets.

Finally, there will be three major challenges in the future aquaculture industry: diseases and bio-security, limiting the effect on the environment and availability of enough raw materials to produce feeds for this fast growing market. PAP will be part of the solution, not only as widely available protein sources, but also to limit the environmental impact of aquaculture, through a higher digestibility of its protein and phosphorus content.

Next, Mr. Jacques Wijnoogst (Tema-International), an expert in aquafeed production and factory design, talked about the difficulties when changing raw materials and introducing new raw materials in a production line.

A successful introduction is only possible through an intense cooperation between the nutritionist and process technologist, whereby the mentality should be “if there is a problem, we will solve it” instead of “we don\'t know this raw material and we don\'t have experience with it, so we don\'t want it”. After all, the future is for the companies who are always trying to be better than the competitors, through innovation and keeping all options open.

After the break, Dr. Dominique Bureau gave an overview of the research he has been doing for more than 20 years on utilization of animal proteins for salmonids at the University of Guelph.

Initially, the low digestibility values measured in those products hampered their inclusion in aquaculture feeds. However, there are huge differences in quality of PAP, due to different processing methods and choice of raw materials. A cooperation between the rendering industry and the University of Guelph resulted in a better understanding of processing methods leading to the production of highly digestible animal proteins.

Dr. Sürreya Özkizilcik (Nutra Yem), Nutrition consultant, gave an overview of the nutritional requirements of Mediterranean fish species, with a focus on the functionality

of hydrolyzed proteins, determination of nutritional requirements, the protein to energy ratios, calculation of metabolisable and digestible energy and how to decide on feed ration.

Finally, Carine van Vuure, manager Nutrition and Regulatory Affairs Vion Ingredients, gave a detailed description of the products produced and developed by Sonac specifically for Aquaculture feeds. There is a wide variety, from animal fats as energy source, blood products, hydrolysates and PAP as protein sources to Calcium Phosphates as mineral supplements.

Research performed by Sonac has shown that Poultry and Porc bone oil, processed to contain more unsaturated fatty acids, can replace partly fish oil in diets for trout without affecting growth or the taste of the fillet.

Another trial showed that digestibility of blood products for seabream mainly depends on the processing method. Spray-dried hemoglobin powder does not affect digestibility of the diet when replacing fish meal. The same result was obtained for Hydrolyzed feather proteins.

Sonac produces several hydrolyzed proteins: Gelatin, MucoPro, Gelko, Kerapro and recently Phosterol. MucoPro and Gelko has been used successfully to replace fish meal in diets for trout larvae, fingerlings and shrimp.

Recently, Sonac developed Phosterol, a natural combination of cholesterol, phospholipids and hydrolyzed proteins, which has proven to reduce FCR in a trial with shrimp.

For the re-introduction of PAP in Aquaculture feeds, Sonac is offering a Porc meal with 60 % proteins and Poultry meal with 70 % proteins.

Apart from the nutritional and cost benefits of these products, a study performed by Ponsioen and Blonk (2010) showed a significantly lower carbon footprint for poultry meal, compared to traditional protein sources such as fish meal and soybean meal. The same picture has been drawn for poultry fats compared to vegetable fats.

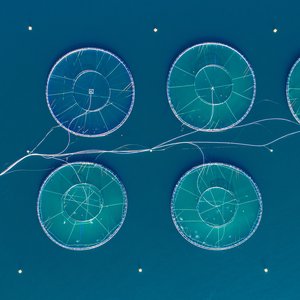

After the seminar, the attendees were invited to tour the factory, guided by the production management. The facilities in Burgum have separated production lines for

Poultry meal, mixed meal, hair meal, blood meal, hydrolyzed feather meal and a new line for Mucopro, for which a completely new technology was developed.

Sonac is the supplier of reliable and high-quality animal-based proteins, fats and minerals. These ingredients are used in food, pharmacy, pet food, compound feed, fertilisers and technical applications. All raw materials are animal-based and suitable for human consumption. Searching for the highest possible value for the various

slaughterhouse by-products is essential. Because of further production process specialisation, active acquisition policy, the geographical dispersal of locations and tailormade products for their customers, Sonac adapts perfectly to the market needs. SONAC is part of VION Ingredients and is active on 37 locations. The Sonac head office is based in Son, the Netherlands.

VION Ingredients: VION Ingredients is one of the two core activities of the VION Food Group, an internationally operating company with two core activities: Food and

Ingredients. VION Ingredients holds a global position in the slaughter-by product markets. Its core activity is adding value to protein and fats. These products are used as

high quality ingredients in such highly diverse markets as pharmaceutics, cosmetics, food, feed, energy and technology. In 2011, VION\'s turnover amounted to €9.5 billion. At the start of 2013, the company employs for about 21.000 staff. VION is not a listed company and has one shareholder, the Dutch Zuidelijke Land- en Tuinbouworganisatie (ZLTO), an agricultural and horticultural association with some 18,000 members. More information.