The Faroe Islands are an isolated island group located in the middle of the North Atlantic. This unique place is ideal for salmon farming because of the stable sea water temperature (between 6 and 11°C year-round) caused by a mix of colder and warmer currents that come together in the Faroe Islands. The location is also ideal to produce premium, healthy, and high-performing salmon as the strong currents keep seawater continuously flowing through the open water pens. Data from the Faroe Fish Farmers Association (FFFA) show that salmon from the Faroe Islands, therefore, have the lowest biological feed conversion ratio (BFCR) of all major salmon-producing countries.

Frontrunners in sustainability

One of the three salmon producers on the Faroe Islands is the family-owned and 100% Faroese company Hiddenfjord. It is the 2nd biggest producer on the island group. In 2021, this company harvested 18,100 tons of salmon (gutted weight), accounting for 19.3% of the total amount harvested in the Faroe Islands. While not being the biggest, the company's mission on sustainability might be bigger than other producers, both on the Faroes and abroad. “Sustainability has always been our highest priority since we started farming salmon in 1982. One of our major milestones recently is that we completely stopped using air freight in 2020, reducing the CO2 emission related to overseas transportation by 94%. To make it concrete: transportation by air to New York causes 7.1 kg of CO2 emission per kilogram of salmon. By using the boat instead, we dropped the emission to 0.35 kg per kilogram of our salmon,” explained Jón Atlason, project manager sustainability at Hiddenfjord.

Next step: New salmon diet

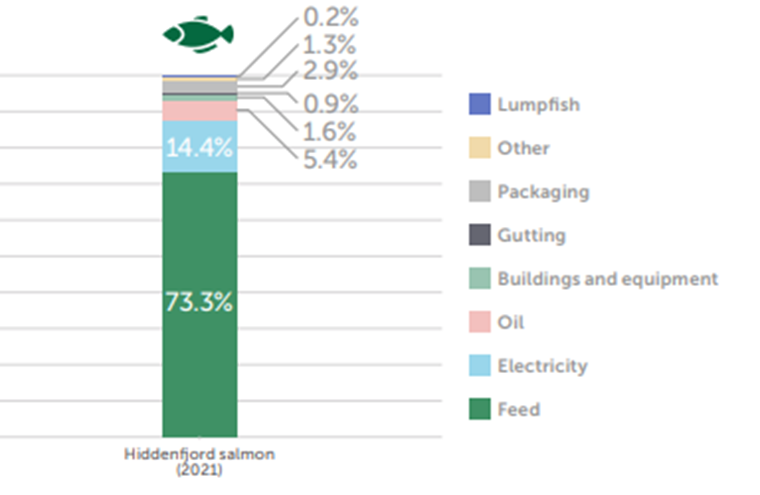

Atlason explains that the next step was to critically look at the feed. “We know that feed and choice of feed ingredients have the highest carbon footprint share in the production of salmon. Over 73% of the CO2 emission for Hiddenfjord’s gutted and packed salmon comes from feed, followed by electricity (Fig. 1). This data, which was also published in our Sustainability Report 2021, was the incentive for us to critically look at the salmon diets and find ways to change the feed, without compromising on performance and health of our salmon.”

Figure 1. CO2 emissions split by source for 1 kg of packaged and gutted salmon. Source: Hiddenfjord Sustainability Report 2021.

Hiddenfjord buys most of its feed from Skretting in Norway. “We started in February this year with a new feed formulation from Skretting. This new feed has a 30% lower CO2 emission per kg feed – including the transport to the Faroe Islands – compared with the previous formulation we used,” Atlason explained. The new feed contains a higher percentage of marine ingredients, compared with the previous diet, and benefits from improvements that have been made in the value chain for Brazilian soy. When using marine ingredients, a focus on responsible practices has to be in place to avoid a negative impact on biodiversity.

As mentioned in the Global Sustainability Report 2021 from Skretting, the highest impacts come from plant-based ingredients, for example, due to agricultural practices such as tilling of the soil, fertilization and land use. Therefore, Skretting is using deforestation-free soy and palm oil sourcing policy. “All soy from Brazil being included in feed produced by Skretting Norway comes from a 100% deforestation-free value chain. Marine ingredients and ingredients from byproducts have a rather low specific carbon footprint, so feeds with high inclusion levels of these ingredients have a generally lower absolute carbon footprint. By 2025, Skretting will source marine ingredients that are 100% certified, or coming from a fishery improvement project for our global operations, a target that Skretting Norway already reached in 2021,” explained Jorge Díaz, global sustainability manager at Skretting.

Lowering the feed waste

But reducing the emissions coming from feed is also about preventing that feed from going to waste, due to mortality and inefficient feeding methods. “It doesn't make sense to feed a ‘sustainable’ diet if the feed ends at the bottom of the pen because it is not well distributed effectively throughout the cage for example. The feeding method must therefore ensure that each salmon is full as well as minimize feed waste. We use cameras and sensors in our pens – located several meters under the sea surface – to identify feed pellets and to control the computerized feeding process to make sure that each salmon is adequately fed and that very little feed goes to waste,” Atlason explained. He added, “our feed utilization is also efficient due to our low mortality rate. A dead fish is simply a loss of nutrients and costs. Our mortality rate stood at 4.94% in 2021, which is considerably lower than the industry average (15%). From 2019 to 2021, we used 1.09 kg of feed to produce 1 kg of salmon (live weight), which is well below the industry average.”

What's next?

At Hiddenfjord, the sustainability mission continues, and the company wants to further reduce its carbon impact in the coming years. “As we purchase all our feed externally, we rely on these companies to invest in the research and produce more sustainable feed. Next to investing in more sustainable diets for our salmon, we have installed solar panels and are investigating the possibility to use wind energy to produce electricity for our sites. All these efforts will contribute to our sustainability goals. I feel that there is pressure on feed companies to find ways to calculate the carbon impact of their formulations and find ways to procure raw materials more sustainable, and there is a lot of acceleration in this field,” Atlason said.

Skretting’s global sustainability manager Díaz added, “we will continue to update the sustainability assessments for feed ingredients, in line with the developments of the market and the needs of their customers. I want to address, however, that sustainability is multi-dimensional and different trade-offs related to the sourcing of the ingredients need to be considered, as well as other environmental and social impacts beyond carbon footprint”.

Atlason concluded by saying that the sustainable targets from companies like Skretting are beneficial for salmon producers like Hiddenfjord. “It leads to new formulations and the possibility to make more sustainable choices. This way, we can keep salmon farming in the Faroe Islands and reduce our emissions.”